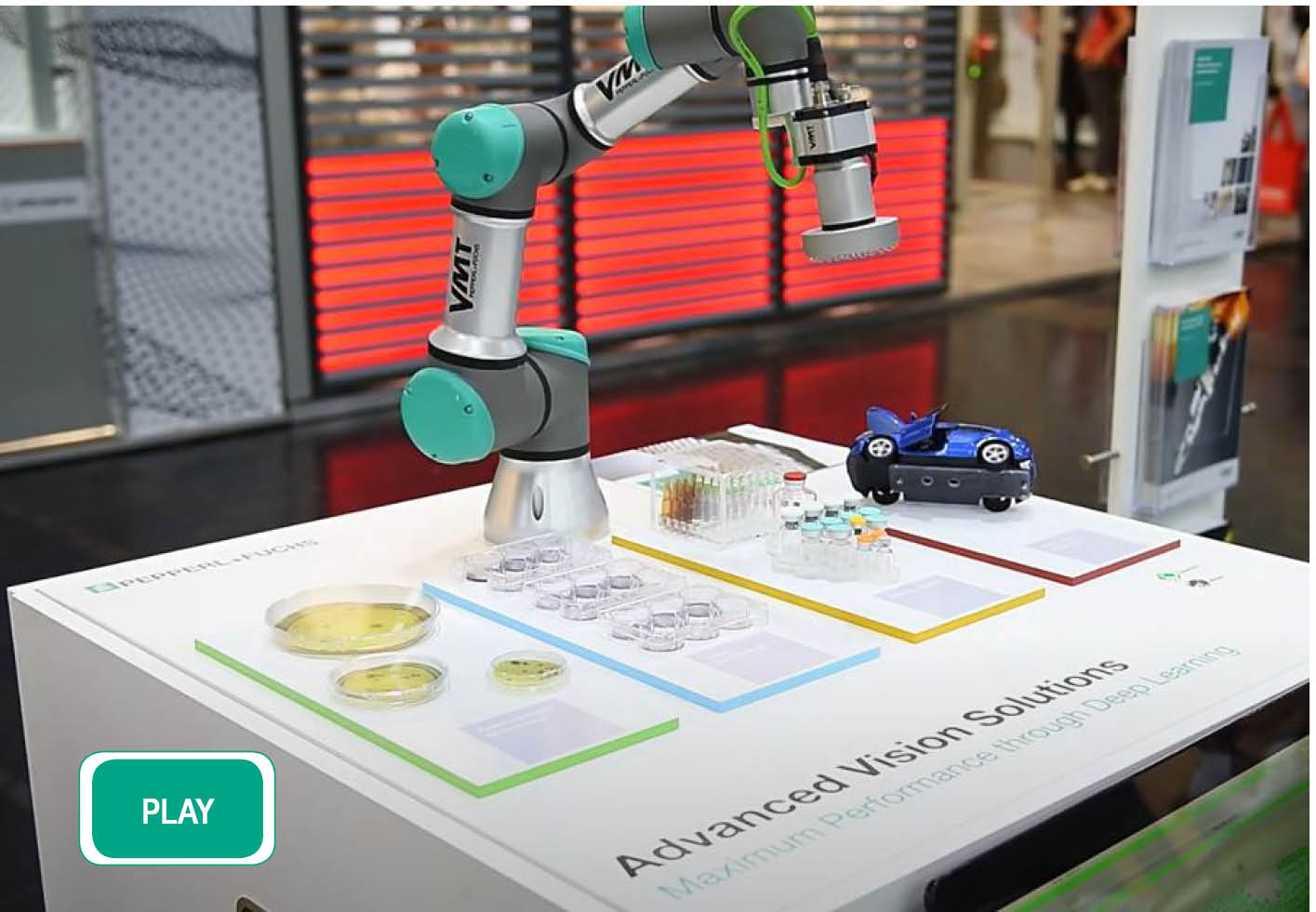

Through an innovative direct printing process developed by Porsche, it is possible to print graphic elements in the highest quality on the vehicle’s painted body parts. Buyers of a new Porsche 911 can initially have the front hood individualized with a design based on their own fingerprint. The brand-new technology called “Direct Printing”, developed by Porsche and partners, also allows us to look into much larger dimensions. This future-oriented technology combines a combination of robot technology (control, sensors, programming), application technology and paint technology, combined in a completely new product range.

Due to the three perfectly integrated components, direct printing enables designs, which would otherwise not be possible with conventional painting. The VMT BK system determines the exact positioning of the body and the deformation of the hood to guarantee the perfect paint application: A print head with 32 individually controllable nozzles, which are mounted on a robot arm, automates paint and applies it to the front hood without spray mist. VMT checks every droplet from the nozzle for direction, separation and size and, as a result, it guarantees that every drop of paint can be applied in a targeted manner.