VMT™ SpinTop

Available now: Next Generation - VMT™ SpinTop G2

In recent years, the VMT™ SpinTop 3D has established itself as a pioneering inspection system for adhesive bead control. In addition to the specially designed sensor with a dual laser triangulation head that rotates around the application nozzle, the complete solution for monitoring bead-like material applications also includes an extensive software package.

Faster, more precise, more efficient – that’s the modern adhesive bead inspection with the new generation. VMT™ SpinTop G2, presented in a modern black design, has been available since March 1, 2024, replacing its predecessor, the SpinTop 3D.

The "Next Generation", the SpinTop G2, sets new standards and impresses with improved performance. The optimal utilization of laser technology combined with robust evaluation algorithms reliably ensures the quality control of the adhesive bead. Particularly impressive are the new vision modules of the sensor, which provide triple the sampling rate at more than double the resolution, enabling more precise and detailed data acquisition.

With the SpinTop G2 transitioning to Class 2 visible lasers, the sensor has a wider spectrum to work with while still providing excellent stability in varying lighting conditions and dark surfaces. The sensor uses a combination of red and blue lasers to allow simultaneous acquisition at high frame rates. This results in new application possibilities and an overall optimized detection process.

The mechanical and electrical connections are identical to the current sensor, enabling easy retrofitting or upgrading in existing systems.

Key Features

The sensor head, which moves independently of the glue nozzle, allows the entire adhesive bead process to be measured. The transmission path for energy and data between the fixed and the rotating part of the sensor head is designed to be entirely non-contact and maintenance-free in order to reduce wear and tear to a minimum.

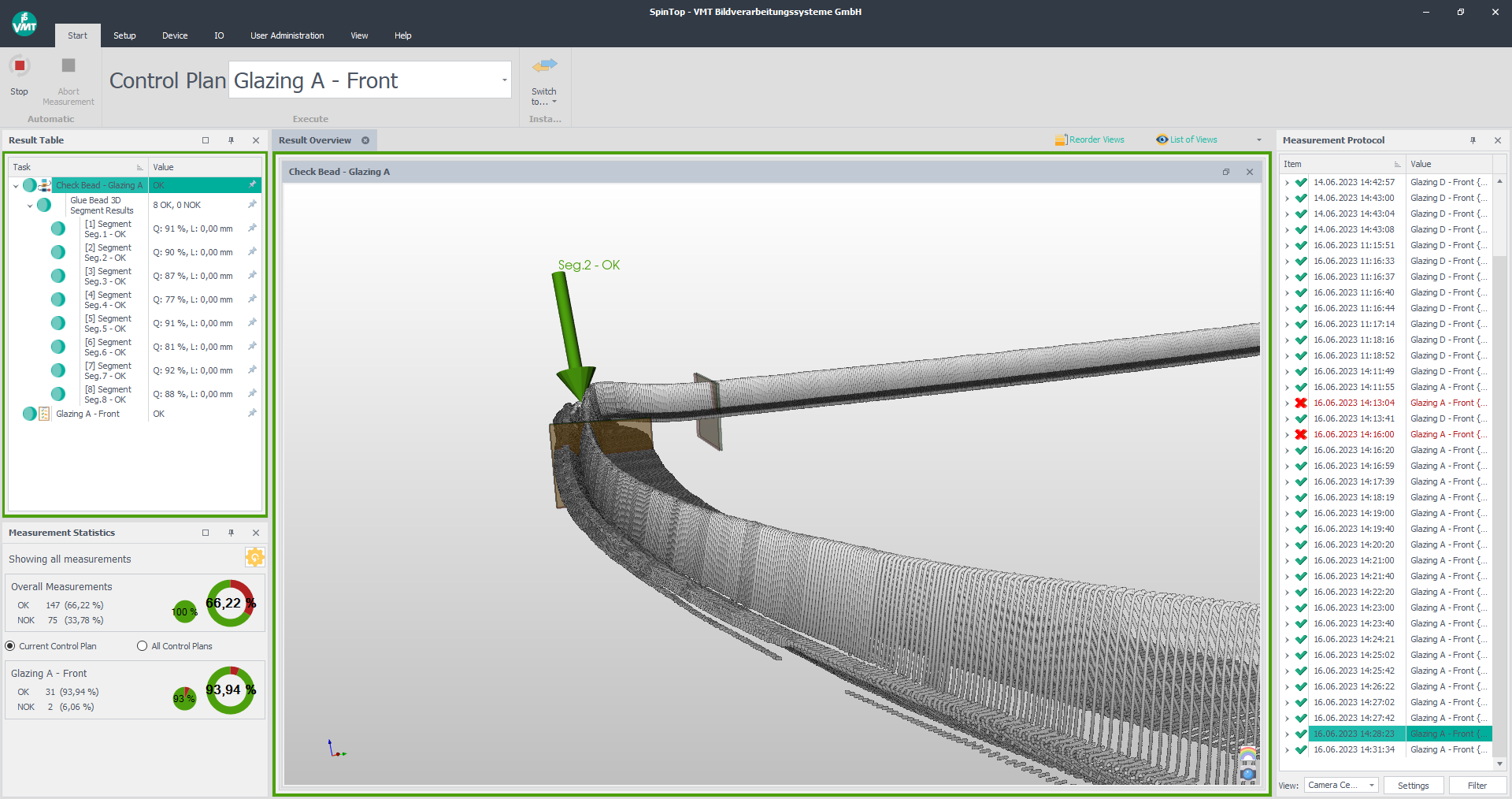

Measurement distances can be selected on a flexible basis, and cumbersome parameterization and calibration procedures are not required. All measurement results can be documented specifically for each vehicle, and can be visualized on the VMT™ user interface in a clear and self-explanatory manner.

- Direct and earliest possible detection of errors during the glue application process

- No reworking costs due to incorrect glue application in subsequent work steps

- Comprehensive checks make it possible to cut down on possible previous glue overdoses

- Cycle time savings through inline measurements directly during the glue application

- Simple retrofitting of existing systems; existing system processes remain the same

- Optimum positioning of measurement technology, since the VMT™ SpinTop G2 is mounted „around“ the glue nozzle

- Minimum interference contours due to compact design

- Customer specific detailed logging - each individual result can be displayed

- Only turn-on and turn-off signals (triggers) must be added to existing robot programs

Features

- Full three-dimensional check of adhesive bead (width, height, continuity, geometry)

- Inline detection parallel to adhesive bead application

- Resistant to color and contrast changes, different surfaces and reflections

- Independent of the glue color - can be changed without new sensor parameterization

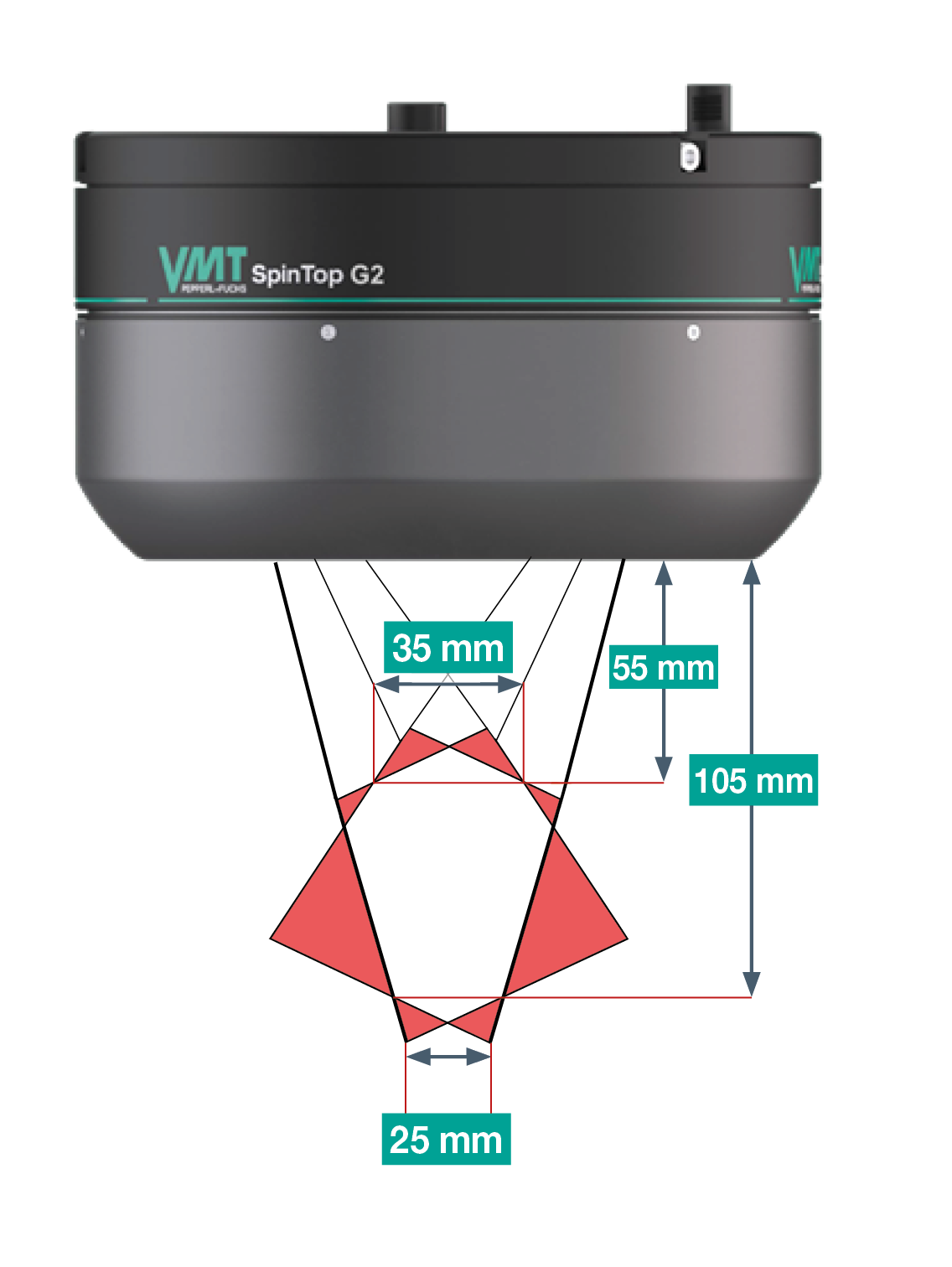

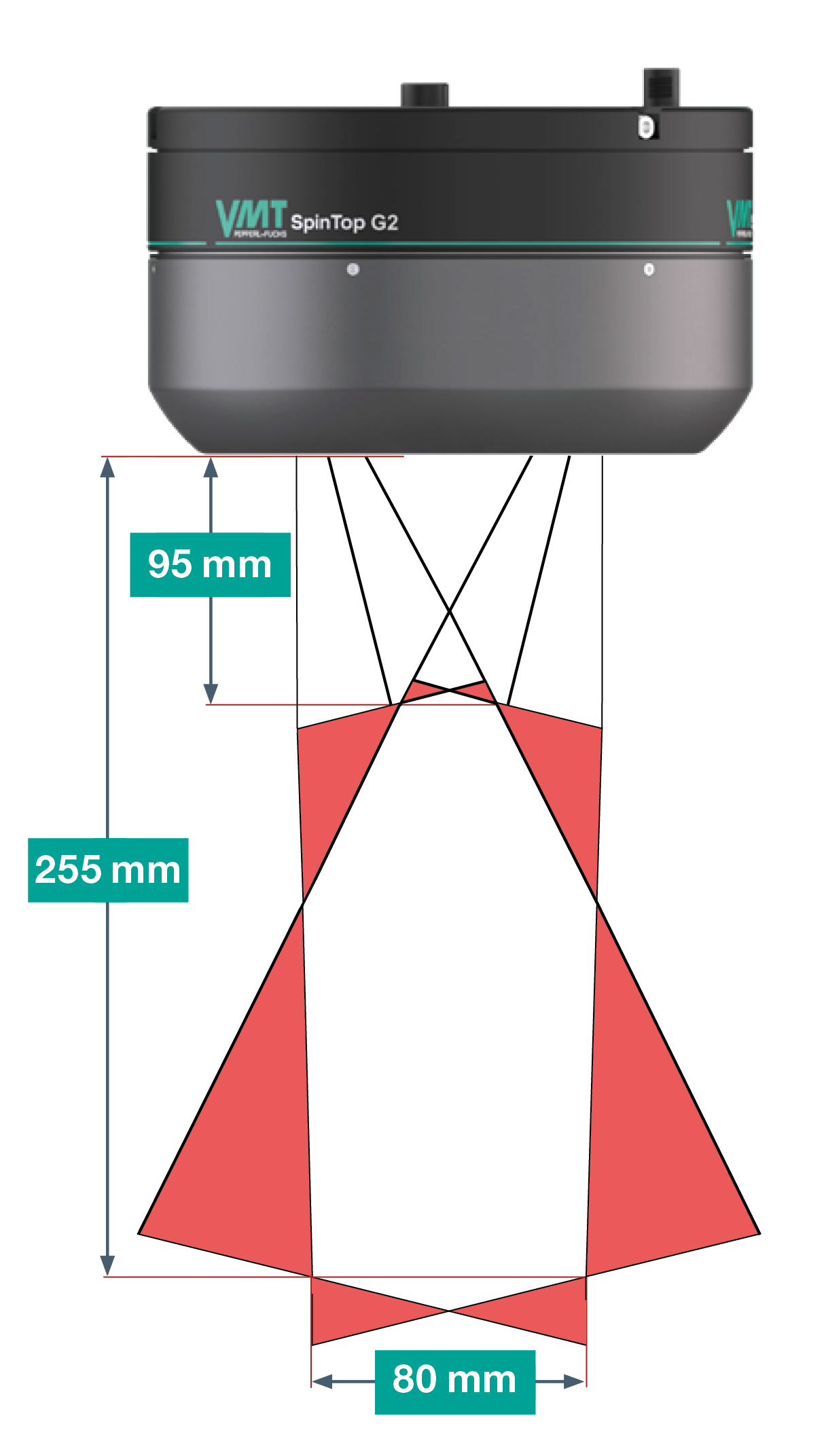

- Flexible measurement distances can be set for the respective glue nozzle lengths

- Two measurement units for optimum capture of 3D geometry

- Free segmentation of test parameters and tolerances

- Freely programmable and robot-independent rotation of sensor unit

- Separate rotation axis for direct inline measurements

- Non-contact, maintenance-free energy and data transmission

- Technology package for communication with robot

VMT™ SpinTop G2 - robot-guided or permanently mounted

The VMT™ SpinTop G2 is mounted directly on the glue gun. The unit can then be guided along the work piece by a robot or it can be used as a stationary version. In the second example, the robot moves the work piece underneath the glue unit. The freely programmable rotation of the sensor unit means that the measurement range can always actively follow the application path.

Installation on the robot wrist joint is risk-free due to non-contact data and energy transmission. Broken cables or wear and tear of friction rings can be excluded. The VMT™ technology package installed in the robot guarantees the exact tracking of the adhesive beads.

Exact path check of the glue beads is also possible with a VMT™ SpinTop G2 that is installed on an existing application unit thanks to the online connection to the robot. The rotation is controlled directly by the VMT™ system. This does away with the separate set-up of a measuring run.

Technological advancements of the "Next Generation" G2

Vision module

- Double resolution

- Up to three times faster capture frequency

- Scan rate up to 900 scans per second

- Perfect for applications such as adhesive application for windows and panoramic roofs, thermal paste for battery modules, and sealant application for battery enclosures

Laser

- High-quality class 2 lasers, lasers emitting blue and red light in the visible spectrum

- Improved capture quality at greater distances and on dark surfaces

- Lateral resolution of 1280 pixels per laser

- Enlarged scannable area

Softwareverbesserungen

- Simplified usability; suitable for non-expert personnel

- Accelerated commissioning of the overall solution

- Modernized interface

- New features such as implementation of warning thresholds

- Redesigned 3D visualization of individual measurements