VMT™ Sense&Place

Automated insertion processes

The insertion of components poses a demanding technical challenge for sensors and data processing due to the sometimes complex, time-critical and high-precision requirements.

VMT™ Sense&Place is an all-round system for this task. Thanks to the interplay of variability and flexibility in the use of sensors, the system can be adapted to almost any conceivable task, regardless of deformation or component tolerances.

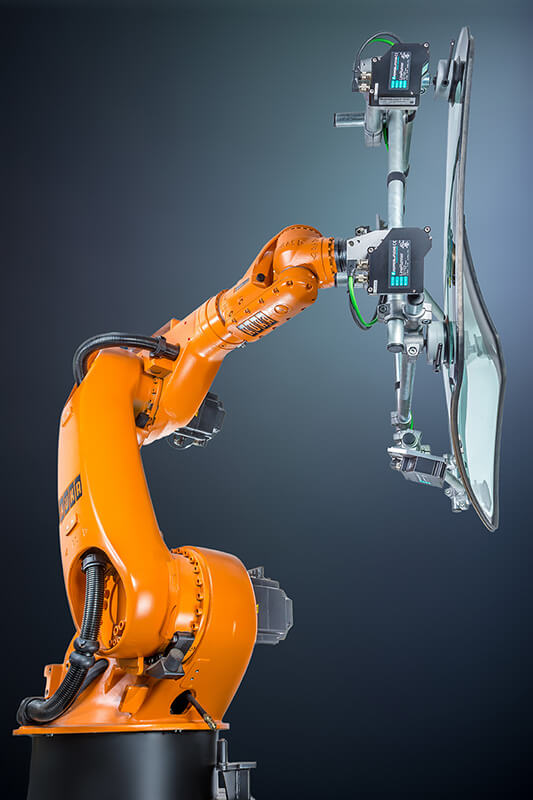

We achieve the right degree of flexibility and speed by using either a fixed sensor, with which the component to be inserted is guided by the robot, or a sensor system specially configured for your component.

VMT™ Sense&Place is based on color-independent light section laser measurement technology, which can also generate height profiles on critical surfaces. This profile data is used by the intelligent VMT™ software and processed into a corrective movement for the robot using a compensation algorithm. In order to minimize programming work, there is a technology package for robots developed by VMT™.

- Flexibility

Depending on the requirements and cycle time, the number of sensors can be selected freely, ranging from a fixed single-sensor structure to an adapted multi-sensor robot tool.

- Color tolerance

Color-independent measurements on different surfaces, in laser protection class 1

- Independence from secondary light sources

Triangulation measurement via bandpass filters rules out the influence of external secondary light sources

- VMT™ technology package

Simple commissioning thanks to a technology package developed by VMT™ (available for all common robot control units, such as ABB, Kuka – KRC and VKRC, Fanuc etc.)

- Calibration

Quick, fully automated and reliable calibration methods, both for a sensor check or a sensor replacement

- Speed

Efficient, single-step transformation correction for the robot

Insertion process with full flexibility

Modern joining processes are subject to complex tasks in terms of automation and flexibility, while accuracy requirements for the installation result are becoming more demanding at the same time. The installation of objects such as doors and flaps in vehicle construction is a recurring task in this regard.

Compliance with gap and flush tolerances is a particularly important sign of high product quality. Consistently good results can only be achieved here if the insertion process can be adjusted adaptively and flexibly to fluctuating body-in-white tolerances, thus yielding a perfect installation result.

VMT™ Sense & Place is a system that reacts intelligently to component fluctuations and corrects the position of the insertion robot so that it can carry out a perfect installation step. A combination of color-independent laser triangulation measurements establishes a stable multi-sensor system is created that carries out reliable measurements and is precisely adapted to its task.

Natural options for using the system include installation strategies such as determining the component position in the target area (best fit) or orientation to fixed zones (alignment). The modularity of the VMT™ Sense&Place system offers a freedom of choice between various established system scenarios, which can reach from a stationary single-sensor systems to cycle time optimized sensor arrays.

How exactly this system is to be structured – flexibly or highly adapted – is something for you to decide, whereby the quality and precision of the measuring results remain insured. In case of unplanned events, the integrated calibration process makes sure that a VMT™ Sense&Place system simply and quickly returns to functionality, and that it even can be constantly monitored during ongoing operations.

Benefit from our experience in countless applications, for example, in the installation of glass panes, doors, hatches and roofs.