Position detection & Robot vision

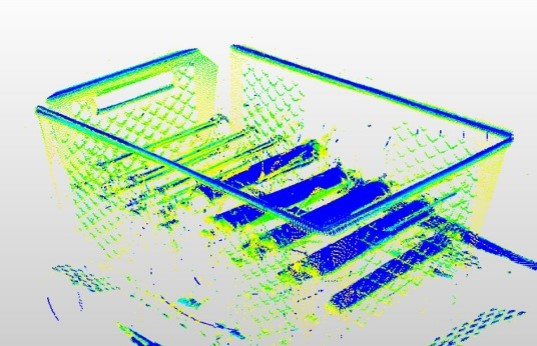

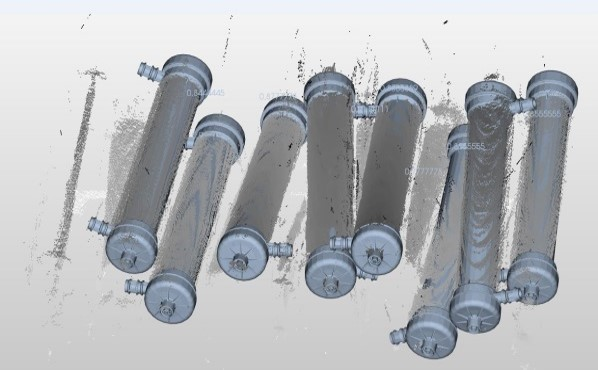

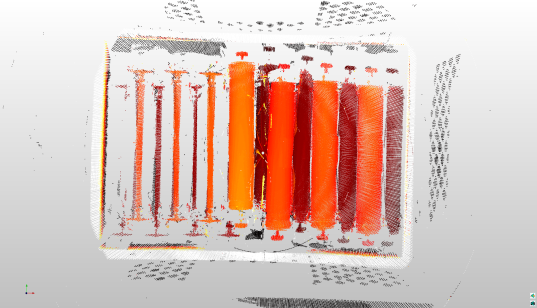

Many assembly and handling tasks require detecting a product's precise position and alignment, and transmitting this information for an automation system, such as a robot, to correctly pick up and position the product. The parts to be grasped might be located on a conveyor belt, arranged in special containers, or jumbled in boxes (“bin picking”).

VMT™ location and positioning detection systems have proven themselves hundreds of times over in industrial applications for all these tasks, with possible position detection of components either on a 2D plane or in a 3D space. Depending on the task definition, stationary cameras, robot hand cameras or 3D laser sensors are used in connection with the VMT™ IS/V image processing system.

The solutions are supported for the broadest range of robot controls and fully automated calibration procedures using standardized protocols. Naturally, position detection systems can also be combined with other tasks, such as inspection or code reading.