HYPROSCREEN™

Digitization of Environmental Monitoring

In pharmaceutical production, equipment, laboratories and people must be regularly inspected for possible germs. For this purpose, thousands of Petri dishes are usually evaluated and documented manually during microbiological surface and environmental monitoring. A cost-intensive, time-consuming and also error-prone procedure!

Our automation solution

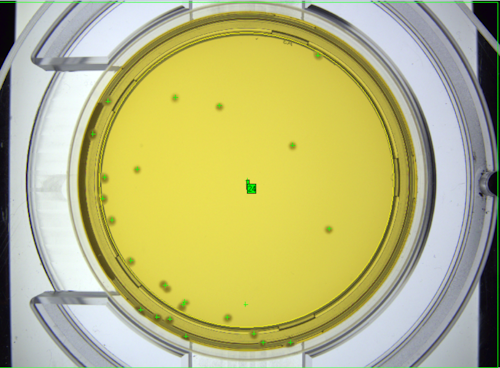

HYPROSCREEN™ digitizes and automates this process. All customary contact or settle plates are captured by our high-resolution camera system and analyzed by powerful image processing algorithms. In this way, even the smallest germs are reliably detected in just a few seconds.

Based on the long-standing know-how of VMT VISION SYSTEMS™ and developed in close coordination with partners from microbiology and mechanical engineering, HYPROSCREEN™ sets a new digitalization standard in environmental monitoring.

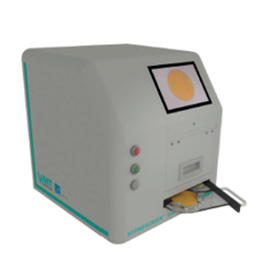

As a laboratory device, HYPROSCREEN™ LAB supports laboratory technicians in their daily routine tasks. Agar dishes are automatically read and assigned based on the label (barcode or data matrix code), and the image data is captured, evaluated and archived. By means of the intuitively operable, powerful software, a subsequent review of data is just as possible as the statistical evaluation of analyses, the creation of reports or the export of data to other DP/ LIMS systems.

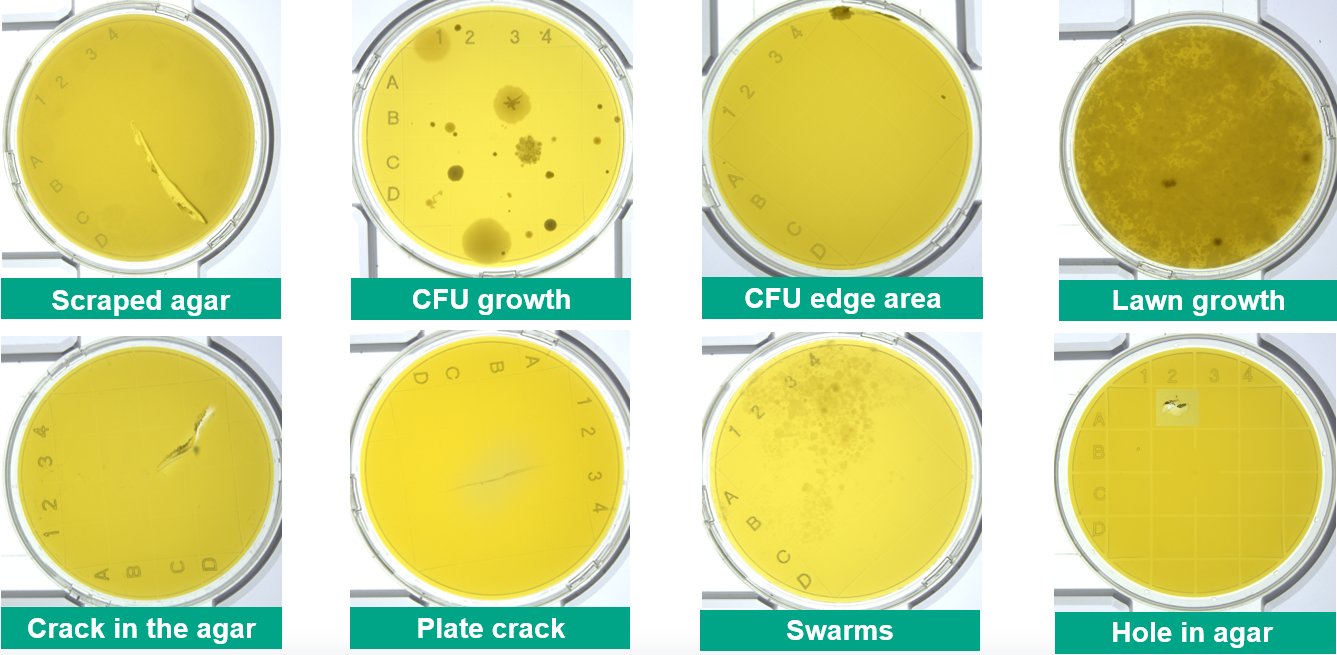

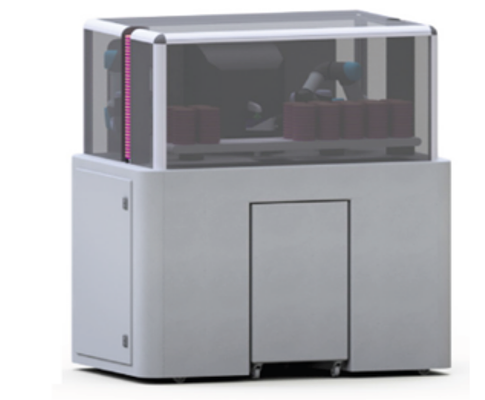

HYPROSCREEN™ AUTOMATE automates the entire analysis process. Plate stacks are fed and processed step by step. Plates are buffered in a magazine and individually fed to the image processing system. The tray lid is removed and reattached automatically for image analysis. Critical plates are separated for post-processing, discharged, or temporarily stored. HYPROSCREEN™ AUTOMATE can process up to 300 media plates per hour, fully automatically analyzing for microbial growth, agar breakage, foreign matter, agar detachment, and other defects, with results documented.

HYPROSCREEN™ LAB and AUTOMATE are fully compatible with each other and can be networked. This also allows subsequent verification of plates with the laboratory system.

Of course, HYPROSCREEN™ complies with all necessary standards and guidelines.