VMT™ MSS

The MSS software platform is the modern core of many VMT™ system solutions. MSS stands for Multi Sensor System, because the software platform does not distinguish whether the image information comes from cameras, laser, or 3D sensors. With versatile tools for image processing, matching, coordinate calculation, logical interconnection and much more, the system can be customized by our engineers or trained staff.

Featuring a user-friendly graphical interface adorned with intuitive symbols and multilingual support, the software facilitates seamless entry without the need for programming skills.

Communication via common industrial interfaces is natively supported, so that the connection to robot controls, cell control systems or cloud servers enables quick and easy integration into new and existing environments.

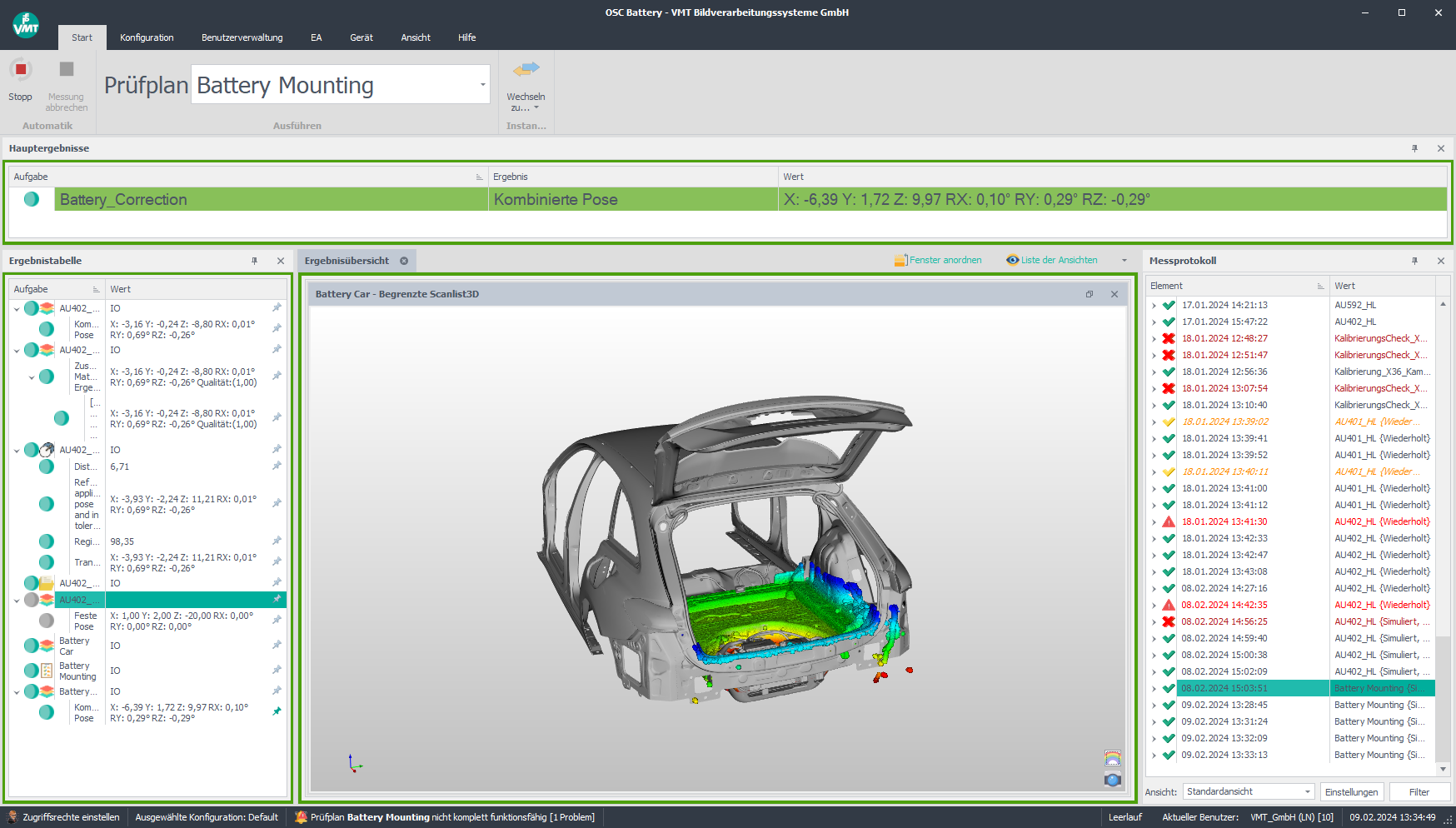

The main view of the software provides users individually with all important process data. Graphical result visualizations, online logging, statistics and in-depth signal analysis can be activated and arranged as desired. For data backup and subsequent analysis, as well as optimization possibilities, measurement results and images can be archived in various formats depending on the time stamp and individual identification numbers, and visualized outside the VMT™ software.

The systems can be expanded with additional sensors, variants, and component types almost indefinitely, either by trained users or, if desired, by VMT™ service teams. Our development team works daily on advancing the software platform, either by improving existing algorithms or integrating new methods.

MSS 2.1 - Software Improvements Overview

Our latest version VMT™ MSS 2.1 is now available, featuring numerous optimizations and new implementations, some of which are highlighted below. For detailed information, please feel free to contact your VMT™ representative or use our contact form.

|

|

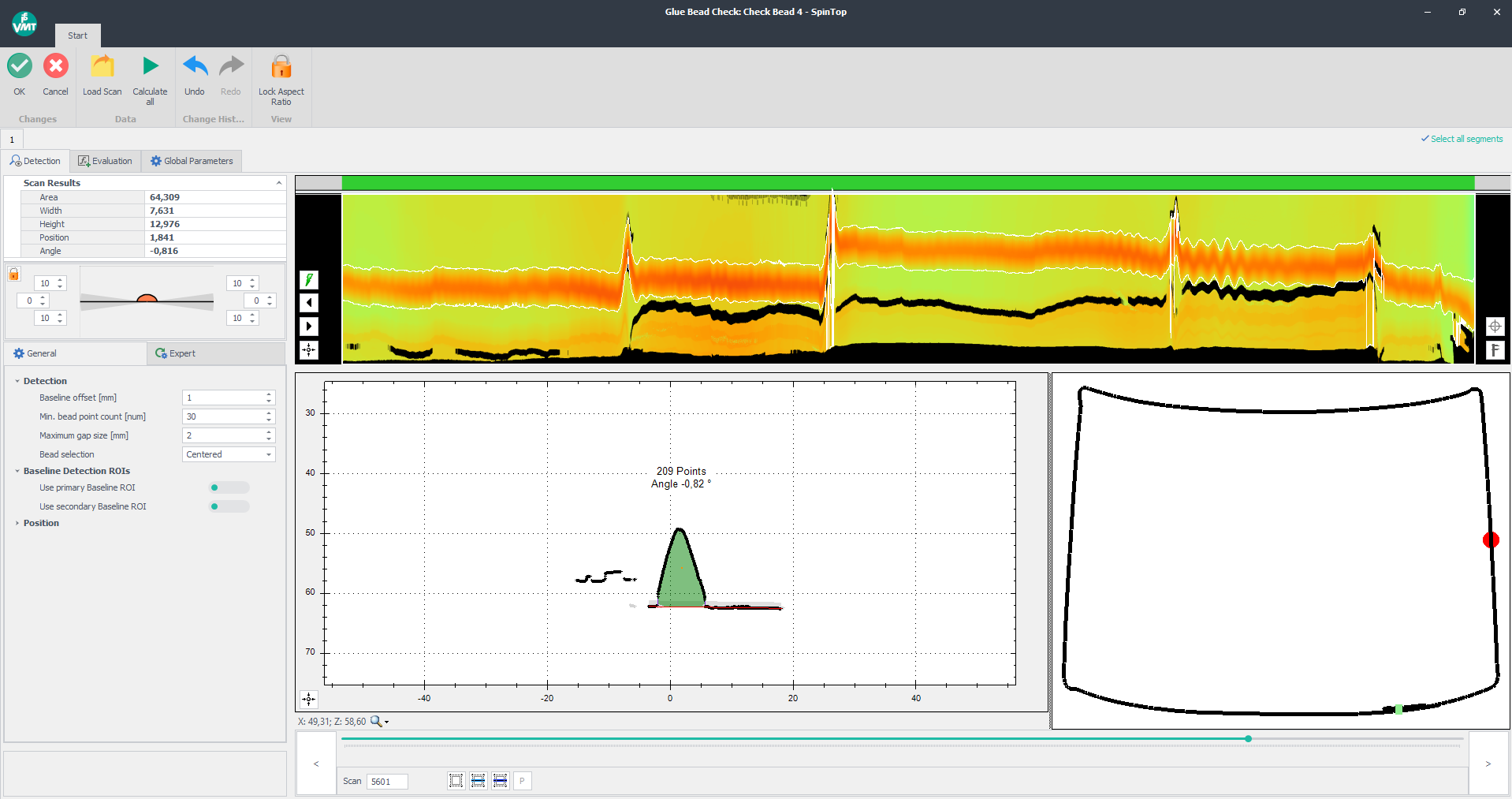

With the release of the new SpinTop G2 sensor, many controls for VMT™ adhesive seam inspection have been optimized. This revision has notably enhanced usability, aiming for an even smoother software introduction for users. This includes menu revisions, streamlining of parameters, setup aids, and more.

|

|

|

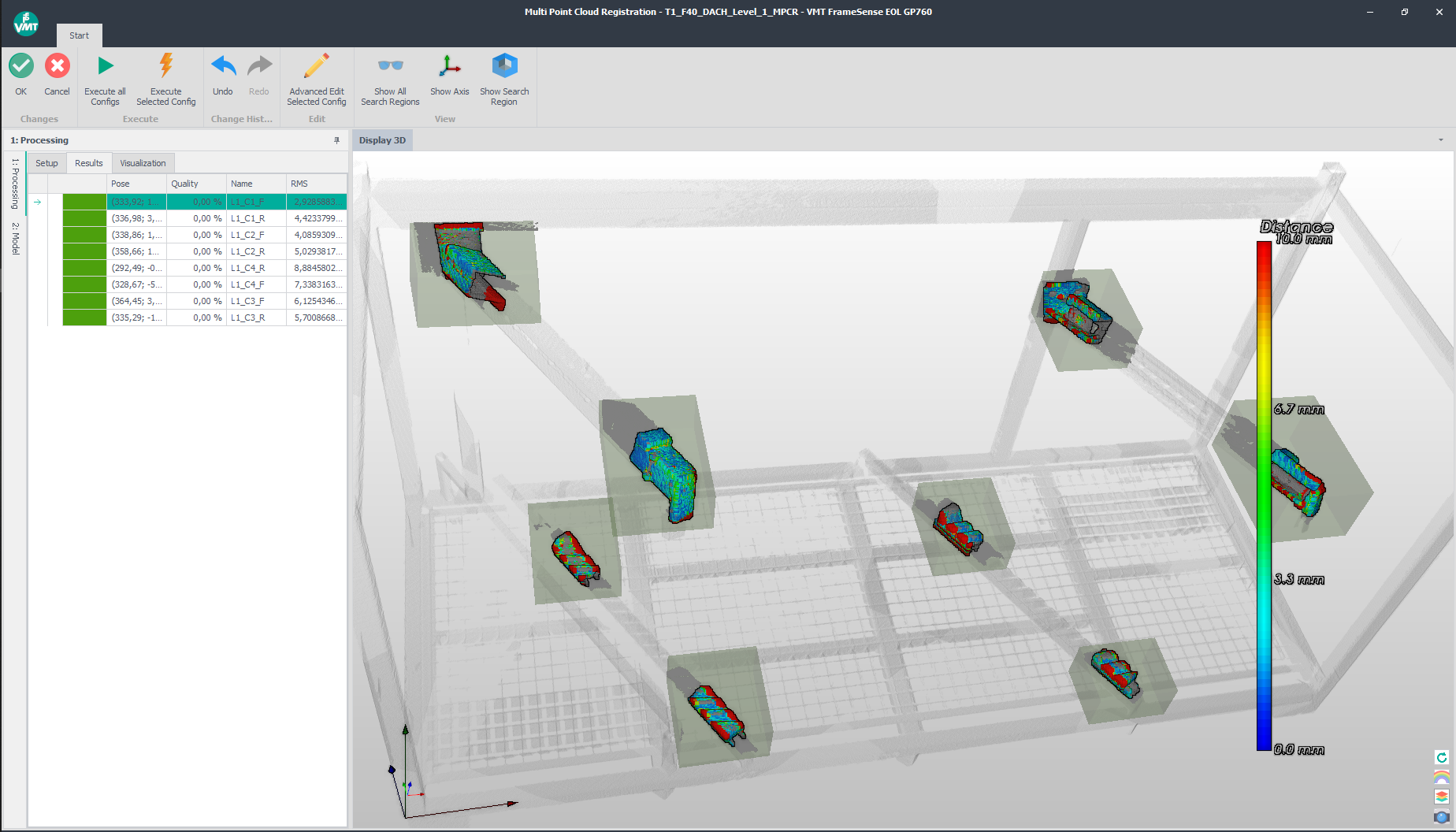

At the beginning of 2023, VMT™ introduced the new product FrameSense for container positioning and inspection. For this application, the existing algorithm for point cloud registration has been further developed. Multiple features can now be detected simultaneously using a reference point cloud or CAD. A total vector is formed from the individual features using a individually weighted positional group. In addition to the additional functionality, there was also a high focus on user-friendly setup.

|

|

|

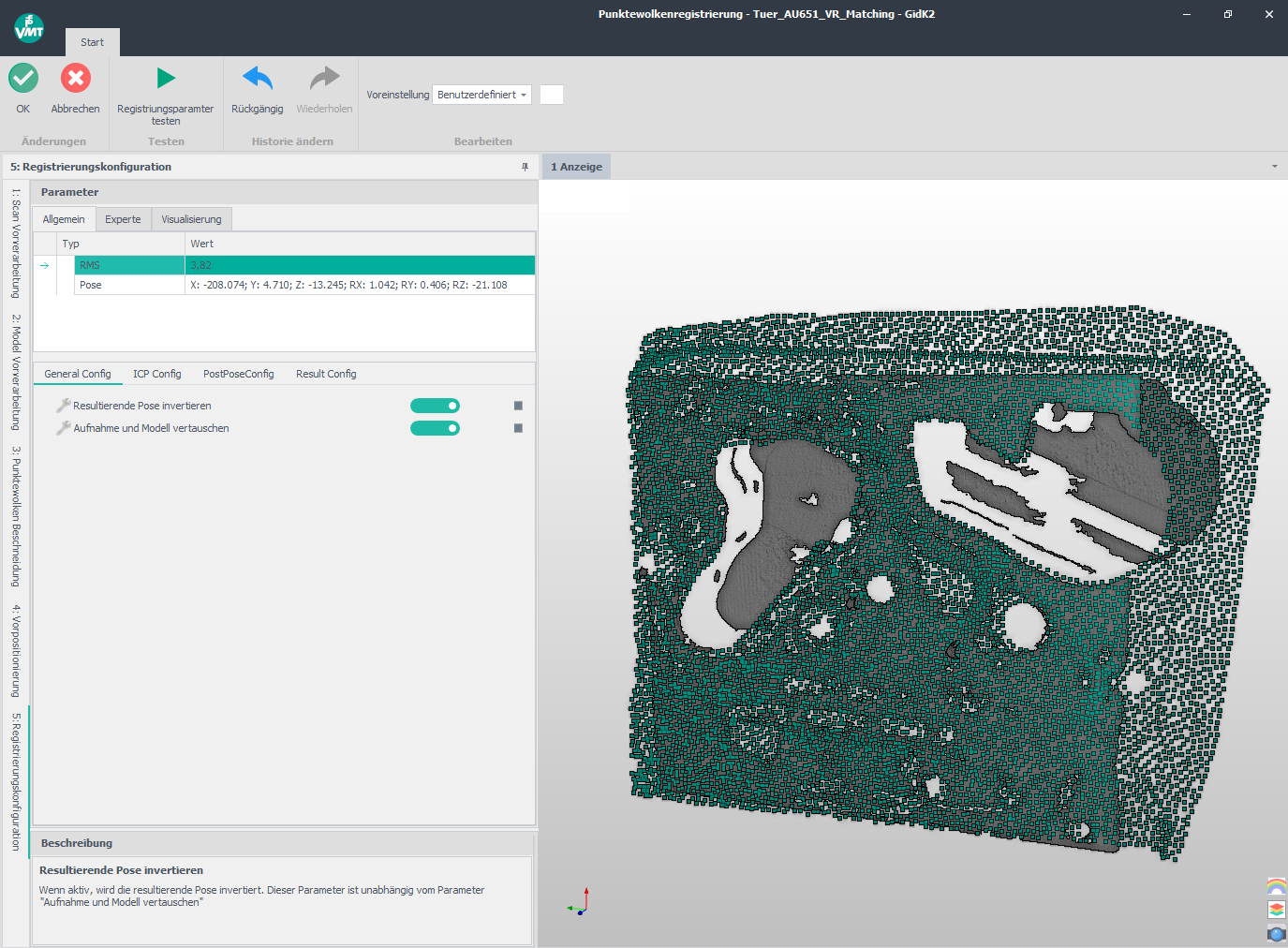

To enhance the ease of use of the point cloud registration, a dialogue has been created, significantly improving workflow and comprehensibility. This notably simplifies the commissioning and maintenance of OSC systems.

|

|

|

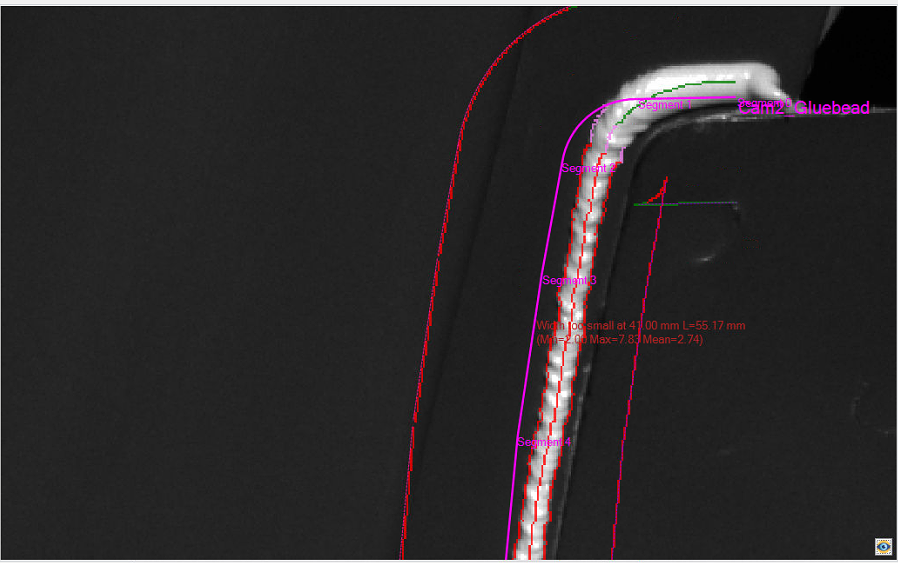

The test task for probing and inspecting contours, used for analyzing glue beads with 2D cameras, has been integrated into MSS. With the help of this algorithm, a contour is detected along a defined spline and then fully inspected.

|

|

|

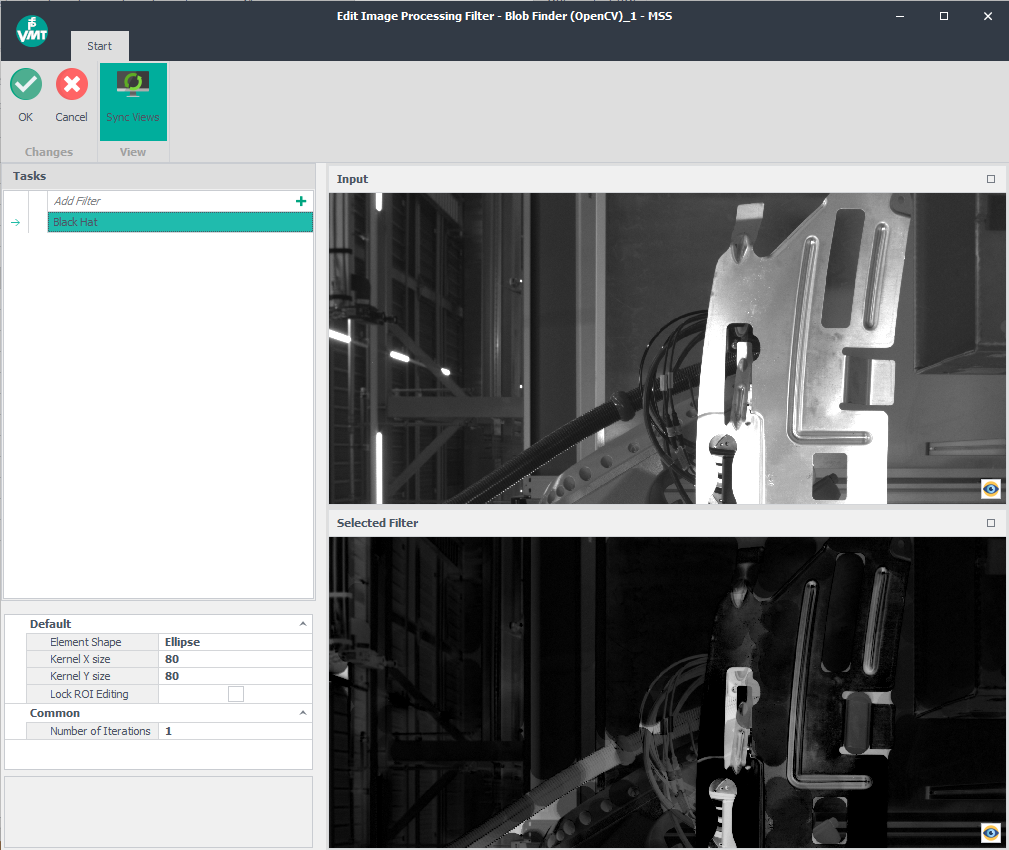

Many new preprocessing tasks have been integrated for preprocessing 2D images. These prefilters enable the solution of more complex image processing tasks by manipulating the raw data to particularly highlight the sought-after features.

|

|

|

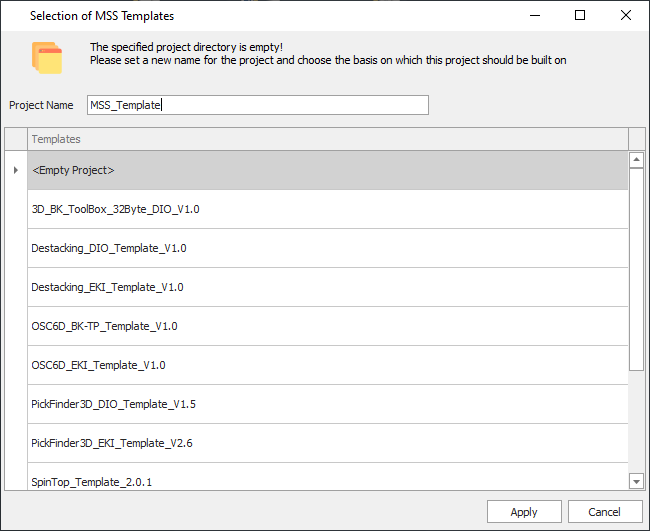

With the MSS installation, templates are now included natively. When starting an empty MSS instance, prepared templates can be selected. These templates are integrated for the solution products of VMT™, allowing direct access to standard configurations for new or test systems.

|

|

|

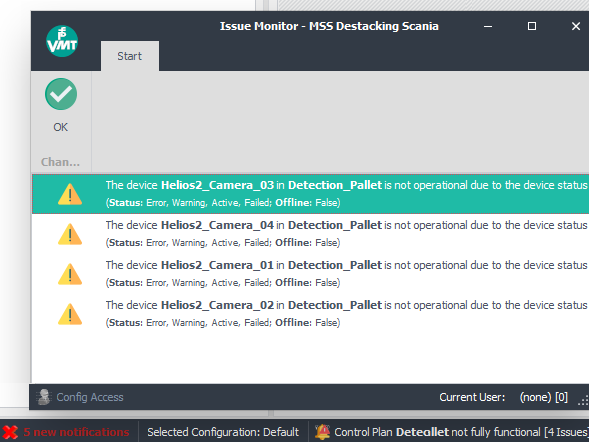

For easier interpretation of the system state, an issue monitor has been added to the bottom of MSS. If a test plan is not fully functional, for example, due to a disconnected or offline camera, a message will be displayed in the status bar. This message is clickable and provides hints about the faulty configuration. |

|

|

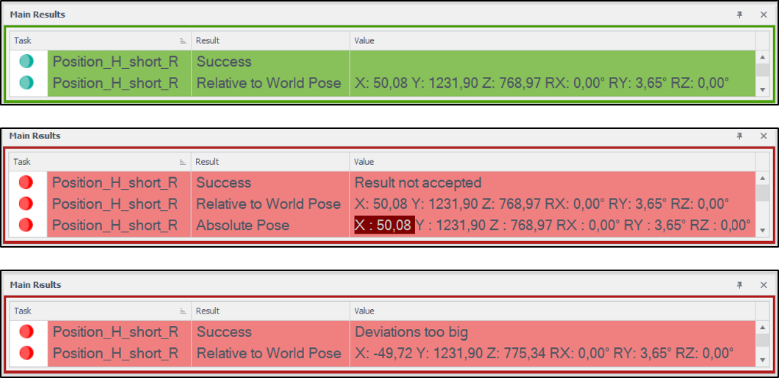

Pinned results in the main outcome will now additionally display a status. For instance, a NIO position detection might be displayed as 'Result not accepted' if threshold values are violated. In this case, the violated value will be highlighted in dark red.

|

|

|

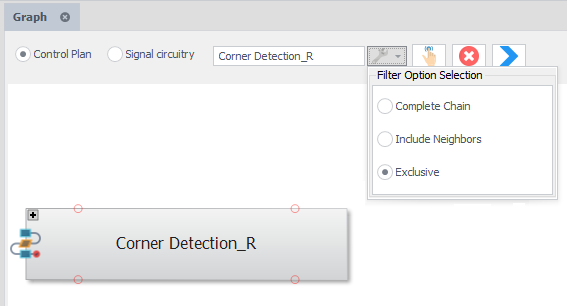

The search functionality in the task graph and signal routing has been revised. For a more effective search, selected test tasks can be set as search filters with a single click. It is also possible to choose whether the entire test plan, only the neighbors, or nothing should be displayed alongside the filtered test tasks.

|

General function expansions in MSS 2.1

|

|

Two new "state of the art" verification tasks have been integrated for reading letters and numbers. Additionally, this feature expansion also incorporates the use of AI support for text reading to make reading as precise and efficient as possible.

|

|

|

In this version, several new sensors have been integrated into MSS.

|

SpinTop Revision

SpinTop Revision