Quality inspection of dialysis filters

Cross-section inspection of fiber bundles for number and pore obstruction

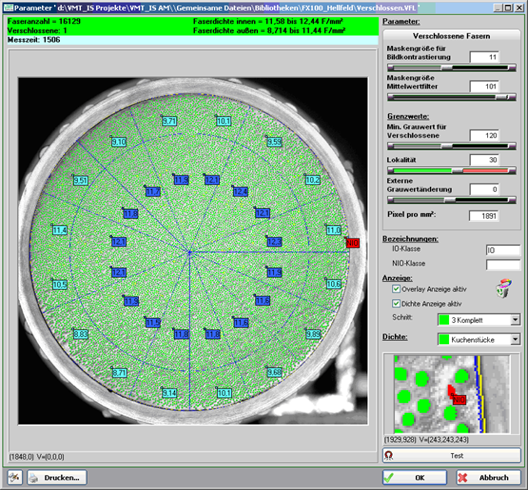

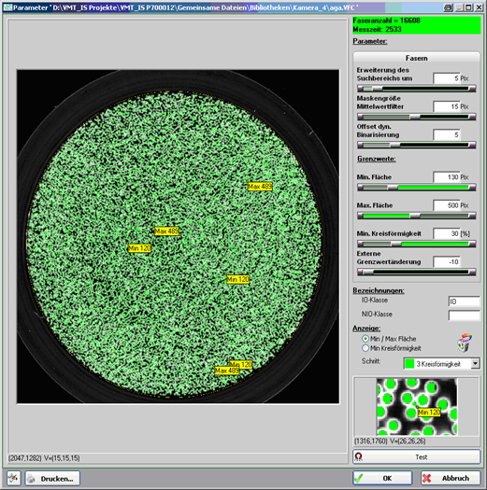

Dialysis filters are made of fiber bundles with thousands of individual fibers. Filters are surrounded at both ends by a filler material and are cut during the procedure. If the cutting quality of the blade decreases, this material can block the fibers, causing the filter to lose optimal effectiveness.

The fully automated inspection must identify and count individual fibers, and where applicable, detect any obstructed fibers. If the number of obstructed fibers is above a defined value, or if these defects are badly geometrically distributed, the filter is removed from production. Additional analysis of fiber geometry for narrowed, flattened or deformed fibers requires an image processing system with the highest possible precision.

With lighting optimized to the physical characteristics of the filter, high-resolution cameras and special detection algorithms, the VMT IS/V image processing system achieves exceptionally high detection certainty with maximum availability.

In addition to end-face inspection, many other inspections have been implemented in the assembly process of medical filters (e.g., assembly verification, geometry inspection, leak testing, fiber bundle inspection, etc.). VMT image processing solutions are now installed worldwide by this renowned manufacturer. Besides the actual solution, global support was also of the highest priority, and VMT effortlessly meets both requirements with its worldwide presence.

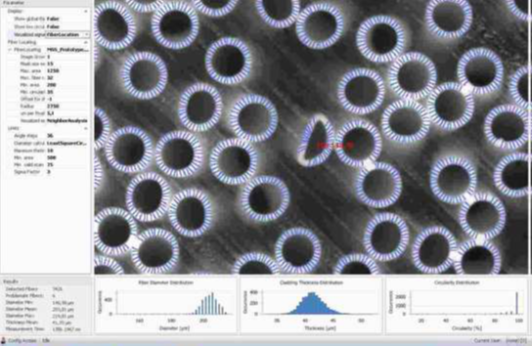

VMT is capable of inspecting the following fiber properties:

- Inspection of deformed fibers

- Wall thickness

- Roundness

- Inner diameter (3 methods)

- Number of flat and pretzel-shaped fibers (see image on the right)