Automatic correction of robot trajectories

using VMT BK

The VMT BK system is an automation process that adapts the nominal trajectory of a robot optimally and individually to the form of any component.

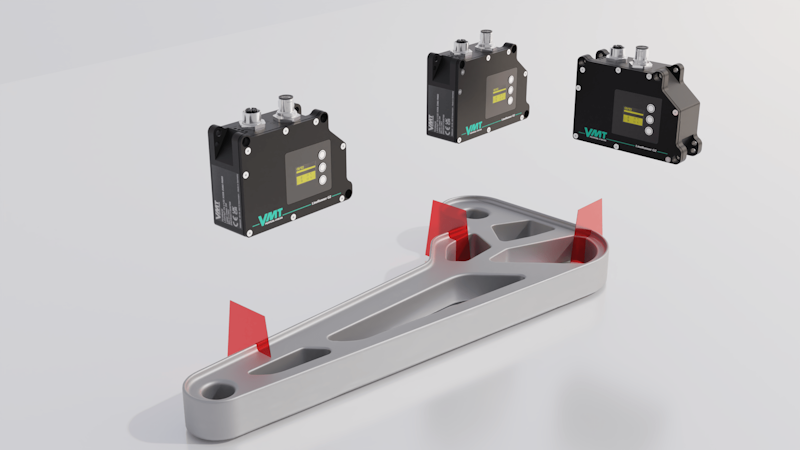

The process is based on three components developed by VMT: The LineRunner, a laser triangulation sensor that generates measured values along the machining contour, the technology package for communication with all common robot controllers and the VMT software for evaluation and visualization.

Advanced automation in different production processes requires an individual processing trajectory that is suitable for the component in question. VMT BK includes the respective component or processing contour and guides the robot along the component in keeping with the data. The use of VMT BK comes into consideration for all robot applications in which a processing tool has to be guided to the respective component geometry.

The different component geometries are the result of production and insertion processes, but can also be caused by unstable components.

- Cosmetic joint sealing in vehicle doors and hatches (flanged seam sealing)

- Precise welding applications, such as those along sheet metal overlaps

- Sewing applications on leather elements for vehicle interiors or, e.g., shoes

Application in detail

The VMT BK system for automated trajectory correction corrects and updates nominal trajectories for robots with an accuracy of +/- 0.1 mm.

Trajectory correction is carried out in a two-stage process. The deviation in component position is first measured to a reference component in a measurement run. Finally, a correction is calculated using the VMT software and the nominal trajectory of the robot is optimally calculated to be adapted to the available component. The result is visualized and can be individually aligned within the VMT working scope. Depending on the laser triangulation sensor used, position and component tolerances in the range of +/- 15 mm can be corrected with high precision.

Measuring run

"The contour of the component is scanned during the measuring run and compared with the reference component. To do this, the robot's VMT laser triangulation sensor is guided along the processing contour. The current 3D position of the component is determined based on the measuring points. This information is used to correct the robot's nominal trajectory with a precision of +/- 0.1 mm."

During the measuring run, the VMT BK system also checks the nominal trajectory of the robot for potential collision risks present in the processing area. If any are detected, an application run is not allowed.

Application run

The VMT BK system calculates an optimal and individual robot trajectory adapted to the available component and relative to the nominal trajectory. If collision-free application is possible, the robot applies the component with high precision and process reliability. On the robot side, the system is operated by a supplied technology package. The package does not require complex programming and is available for all common robot controls.

The robot can thus carry out its processing tasks with the highest accuracy.

System advantages

Flexible and expandable, even with the most demanding applications, VMT offers individual and optimal solutions. The market-tested automation system ensures high system availability, process reliability and system capacity.

- Automated tool data determination

The VMT BK sensor is internally calibrated at the factory. The measurement results are therefore specified in millimeters. Using a simple, automatable process, it makes it possible to determine the tool data of the sensor on the robot quickly and precisely. The sensor TCP data can also be checked at any time.

- Measurement data management

The VMT BK system solution seamlessly logs all system activities and measured values. It can be linked to a database for long-term data storage.

- Robust sensors

The VMT LineRunner (laser triangulation sensor) works in the infrared range, making it robust with varying lighting conditions, surface properties and backgrounds.

- System expansions

In addition, the BK module can be expanded to include any VMT software module: 3D position determination, 2D position determination, inspection and many others.

- Optimizable application for component shape deviations

The VMT BK system can be individually adapted to the component’s shape and stability. The number of measuring points can be scaled and is adapted to the component’s requirements. The scalability of the system allows to correct the position of the entire component, different areas or even individual points. VMT BK enables the reliable detection of every geometrically detectable contour such as component edges and sheet metal overlaps.

Read more about the VMT LineRunner laser sensor...

VMT CloudBK – The Next Generation of Path Correction

We are expanding our powerful portfolio in the field of path correction: With VMT CloudBK, we are taking path correction to a new level.

VMT CloudBK utilizes state-of-the-art point cloud sensor technology to create a fully digital representation of an object with just a single scan. Instead of individual point measurements taken during a measurement run with the robot, VMT CloudBK enables a comprehensive capture of the component geometry, from which any number of virtual cross-sections can be extracted. These virtual cross-sections can be used for precise position correction – without requiring additional robot movements.

While the proven VMT BK technology remains indispensable for high-precision applications, VMT CloudBK offers a more efficient, flexible, and cycle-time-neutral solution for many new applications.

The Advantages of VMT CloudBK at a Glance

Maximum Efficiency

All relevant image data is captured with just one sensor scan—eliminating additional robot movements and saving valuable time.

Highest Flexibility

Virtual cross-sections can be set as often as needed and at any desired position—without reprogramming the robot or extending the cycle time.

Scalable Sensor Technology

The point cloud sensor technology used can be flexibly adapted to specific requirements—factors such as working distance, required field of view, and necessary resolution play a crucial role.

VMT CloudBK and VMT BK – The Perfect Combination for Maximum Precision

With VMT CloudBK and VMT BK, we offer a unique range of path correction technologies that can be optimally combined depending on the application. While VMT BK is ideal for high-precision applications such as welding, seam sealing, or stitching, VMT CloudBK enables fast, flexible, and cycle-time-neutral acquisition of complex geometries. Together, they drive the industrial processes of the future, ensuring the highest quality, efficiency, and flexibility in production.